cecoenviro.com

1st July 2021

Before undertaking any industrial noise control work, we recommend a full acoustic analysis to ensure any solutions installed are efficient and cost-effective.

There are significant implications (financial, regulatory, planning hurdles or public perception) for businesses, industry and developers who either operate or intend to install assets which emit noise, and where the acoustic assessments are not sufficiently competent or detailed.

A poor approach could mean achieving or failing a noise at work noise target, or alternatively upsetting nearby residents in an environmental noise situation, all because the frequency content of the source noise has not been adequately considered, and a full acoustic analysis has not been undertaken.

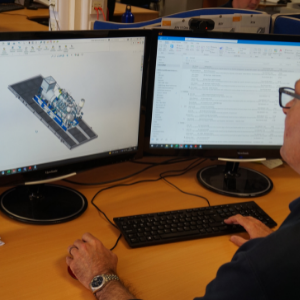

Before our design and engineering team bring into realisation an acoustic solution for our clients, there are important prerequisites that we must carry out in order to provide the best service possible. One of these prerequisites is a thorough acoustic analysis.

When selecting plant and equipment for a site which requires noise control solutions to be implemented, it is essential to undertake a detailed acoustic analysis to ensure the desired results are achieved. From past experience, when selecting equipment such as acoustic enclosures or barriers, we have been presented with nothing more than a broadband overall A-weighted noise level. Though this information is very useful when assessing noise at work or environmental acoustic issues, this does not give sufficient information to allow the implementation of a noise control solution.

For a thorough acoustic analysis, it is essential to work from a frequency spectrum of the source noise in order to achieve the desired solution. All materials, including acoustic panels, have differing performances across the frequency spectrum, with mid-high frequency noise the easiest to reduce from a conventional acoustic panel system. We look at all of this during an acoustic analysis.

For example, a typical 50mm thick acoustic panel enclosure could have as-fitted sound reduction properties of approx. 8dB at 63Hz, increasing to circa 45dB at high frequency. For noise sources which emit a mix of low, mid and high frequencies, it could be expected that an acoustic panel enclosure would give around a 15dBA overall reduction. However, should the frequency content be dominant at low frequencies, the reduction could be as low as 8dB, and conversely for high-frequency noise sources, the reduction could be as high as 45dBA.

Wakefield Acoustics are specialists in industrial and commercial noise control solutions, where we undertake the design, manufacture and installation of a range of acoustic enclosures, acoustic louvres, screens and attenuators. Our specialist knowledge in the industry allows us to provide a thorough service for our clients, utilising our years of accumulated experience to manufacture tailored solutions for all acoustic problems. Contact us today to learn more.